welcome to my blog

This blog will be about the profession of supply chain management. Last summer, I had an internship at TCL’s headquarters in China (a very well-known brand in the field of TV sets) for two months. Because I was more interested in supply chain management, I was assigned to relevant department. I also took a course in supply chain management this semester. However, what the teacher said is to build a large framework of knowledge for us, which is complete but not practical. I will use this experience to briefly describe modern supply chain management and compare it with the past. This blog will include the following points: sales and production expectations management, procurement and inventory management and future changes in supply chain management.

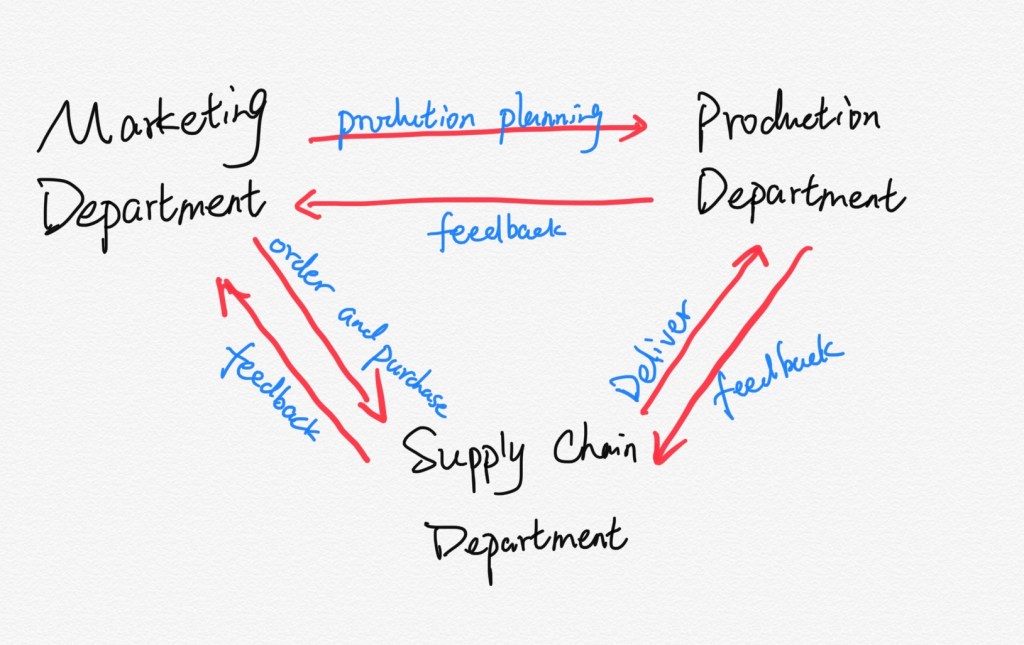

Business cooperation is a framework in which mutual cooperation and the flow of information between organizations run (Blankenburg Holm, Eriksson & Johnson, 1996). My first point is the management of sales and production expectations. With fixed assets unchanged, every manufacturing industry has a fixed capacity. However, the task of maximizing capacity is not only the function of the production department, but also one of the main functions of the sales department and the purchasing department. Why do you say this way? The sales department will give the production plan to the procurement department, and the procurement department will be responsible for the procurement of related products, and then deliver it to the production department to implement the product. At the same time, TCL implements the ‘Just in time’ (JIT) strategy. In order to respond to customer needs and increase product profits as quickly as possible, the purchasing department must reduce procurement time and product profits, including the choice of our suppliers and transportation methods s Choice.

How to link sales department, purchasing department and production department? Before computers were invented, their connection was based on paper to transmit information. This was not only slow, but people’s writing was prone to errors, which caused economic losses. However, since the introduction of computers, the speed of information transmission can be said to have changed qualitatively. In order to implement the JIT strategy, TCL has designed a system program for the company as a whole. It can not only observe the company’s production, inventory, etc., but also directly integrate TCL suppliers into the system, which means that salesmen can delivered orders to the purchasing department, and the purchasing department directly orders to the supplier through the system.

The second point is procurement and inventory management. Good inventory management is very important because too low inventory may cause oversupply, and too high inventory will increase fixed costs. The social responsibility of participants in the supply chain is an effective tool for planning, coordination, procurement, production, distribution and marketing or sales (Ferrara, Kademi, Salimi & Sharifi, 2017). So, the main cause of inventory backlog is inaccurate forecasting, which leads to too many purchases, too late to produce consumption, or too much production to sell. Here, TCL set up a safety stock for each hot-selling product and eliminated products with low sales. Some people would ask how to predict? Prediction is actually the result of statistics and analysis of a data. Previously, each company had a department dedicated to statistically analyzing these data and analyzing sales and estimating future production trends. However, now that everything has been digitized, the computer can directly analyze a reasonable, low-risk safety stock using related programs. This greatly saves manpower while reducing production costs.

Finally, changes in future supply chain management. The current digital economic management model has been adapting to the use of various enterprises in various fields, especially the popularity of online sales, which has spawned new consumption models and spawned express delivery companies. As long as people buy something on the Internet, the order number will be automatically generated in the background to facilitate customers to track the location of the goods. However, although TCL implements digital information transmission on the system, and strengthens and controls the activities of the internal supply chain, it still does not understand the activities of the external supply chain, so that it is often the case that goods cannot be delivered on time, because on the system I cannot see the production status of each supplier and the location of the goods. If the production activities of some of their companies can be integrated into a system, the risk will be greatly reduced, and the demand side can monitor the situation at any time and make relative changes in time. By the way,The benefit of integrating strategic partnerships is that organizations gain time and reduce costs (Nishi & Grossmann, 2015)

Although the demand side can control the dynamics of the supplier at any time to reduce the risk, this involves the privacy of the supplier. This is good for the demand side and bad for the supplier. In the environment of fierce competition from the outside, increasing their internal transparency is very vulnerable to external stimuli, such as vicious price competition. Finally, if you are also interested in the profession of supply chain manager, you can try it. After a period of time, you will find its charm.

Reference

1. Blenkenburg Holm, D., Eriksson K. & Johanson J. (1996). Business Networks and Cooperation in International Business Relationship. Journal of International Business Studies, 27 (5), 1033-1053.

2. Ferrara, M., Khademi, M., Salimi, M. & Sharifi, S. (2016). A Dynamic Stackelberg Game of Supply Chain for a Corporate Social Responsability. Hindawi Publishing Corporation Discrete Dynamics in Nature and Society, 2017 (1), 1-8.

3. Nishi, T. & Grossmann, I.E. (2015). Optimal quantity discount coordination for supply chain optimization with one manufacturer and multiple suppliers under demand uncertainty. Int J Adv Manuf Technol 76, 1173–1184.